Ultrasonic Leak Analysis

Spectrocity uses ultrasonic and sniffer technology to detect and quantify leaks. The most common service being the detection of compressed air leaks. Compressed air leaks are very common and account within organisations for significant financial losses . This service allows the customer to do simple repairs that can yield large cost savings.

Detectable Gases

Spectrocity detects leaks in the following gases:

- Compressed air

- Vacuum

- CO2

- N2 (azote)

- Oxygen

- Natural gas

- Carbon monoxide leaks

- Steam

- Helium

- Hydrogen

Surveying and Reporting

Leaks are located using sensitive ultrasonic sensing equipment. Helium and hydrogen leaks are detected using a sniffer. All detected leaks are tagged with an ID used for the report. The leaks are photographed along with measurements. Surveys are non invasive and can be performed during normal running times. Large sites can be surveyed quickly using Spectrocity's latest technology.

On completion, major issues are reported to the customer and a comprehensive report is supplied. Details of each leak including location, size, cost of leak and repair recommendations are reported. We aim to issue a report within 3 to 4 days of the survey.

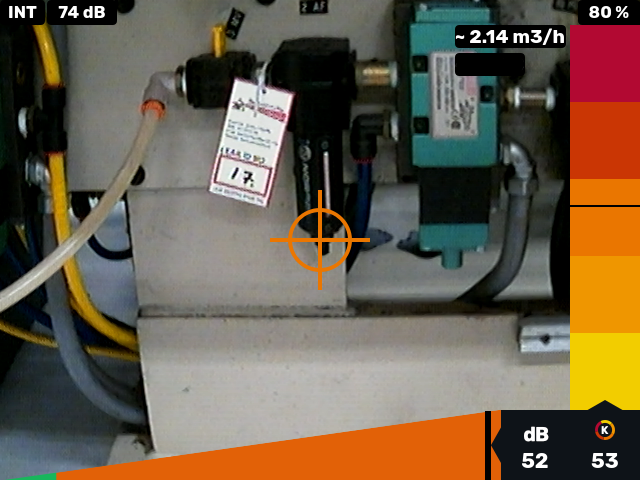

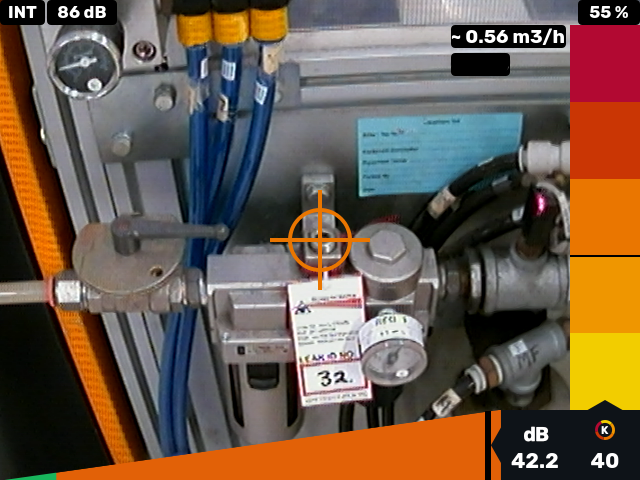

Some examples of fault detection's can be seen below.

A brief description of the faults can be seen on the bottom of the images.

Fitting to 2AF air filter with a leak on the bleed screw.

Fitting to 2AF air filter with a leak on the bleed screw.

The grub screw shown on the FRL is the source of the leak.

The grub screw shown on the FRL is the source of the leak.